The Artemis 1 Space Launch System {SLS) rolls to Launch Pad 39B on March 17, 2022. Credit: Scott Johnson / SpaceFlight Insider

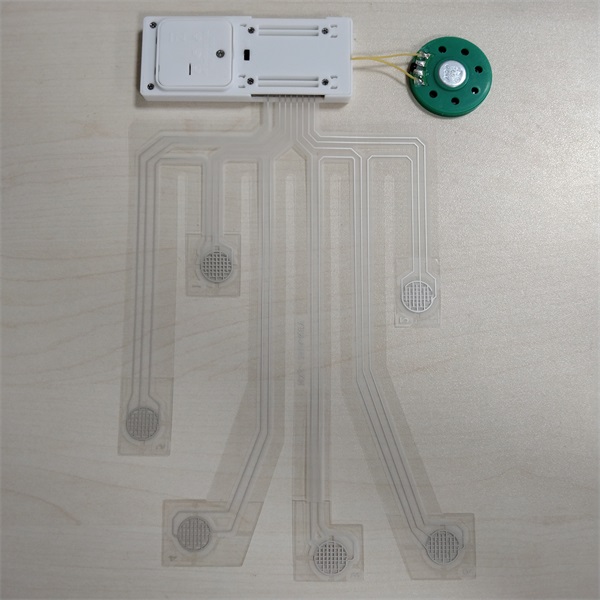

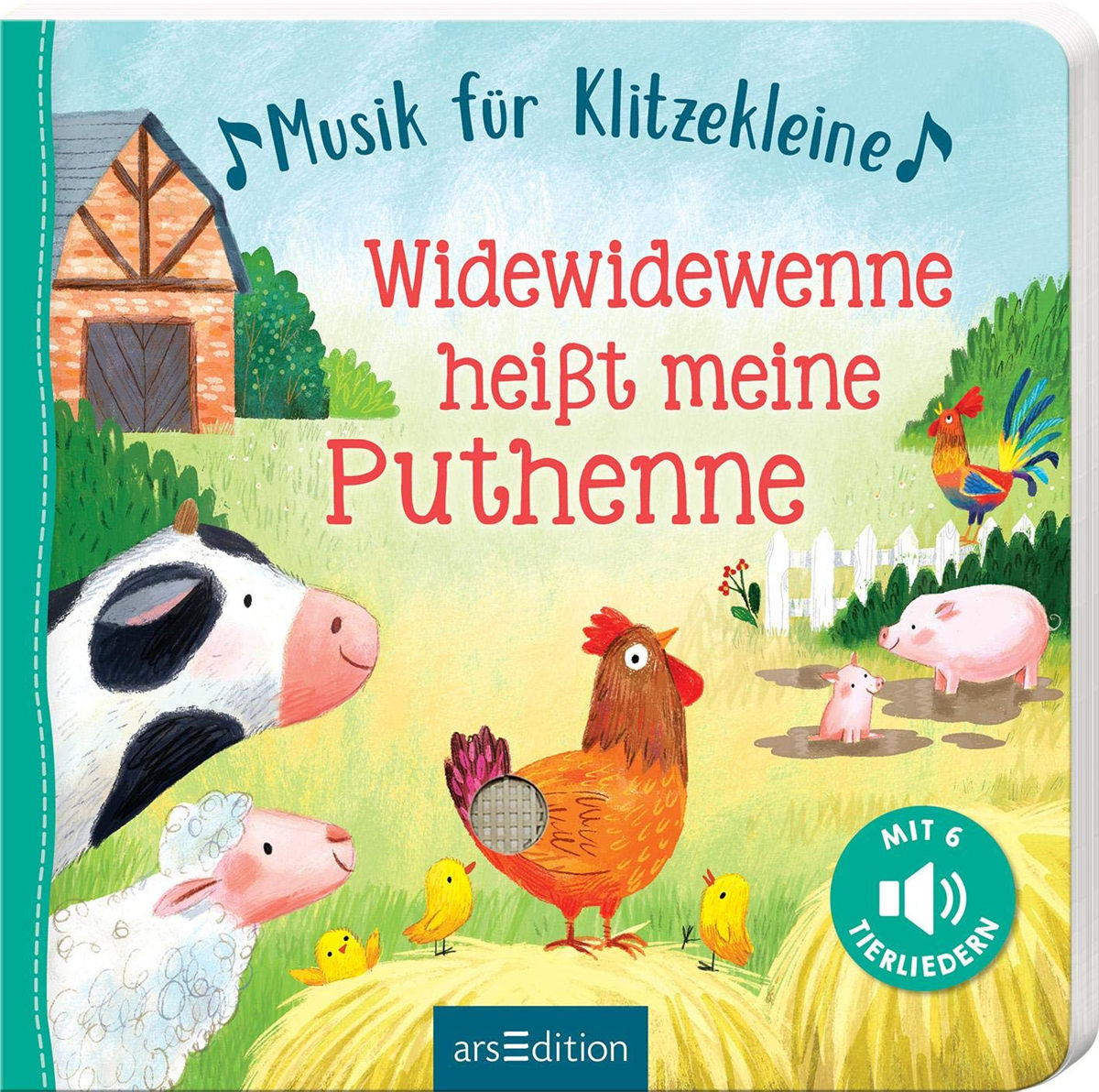

KENNEDY SPACE CENTER, Fla. — In the lead-up to the first Artemis 1 Space Launch System (SLS) launch attempt, Spaceflight Insider had the opportunity to speak with a number of people involved in its design, construction, assembly, and flight. One of those people is Mike Hawes — Lockheed Martin Space Systems Company vice president and Orion program manager. Projector Toy

A portion of our conversation with Hawes is below.

Gary Napier, communications manager for Lockheed Martin Space Systems Company, also participated in the discussion.

Mike Hawes, Lockheed Martin Space Systems Company, Vice President and Orion Program Manager. Credit: Challenger Center for Space Science Education, Inc.

SpaceFlight Insider: I think you told me earlier your full name is William Michael Hawes, and you go by Mike, but where are you from originally?

Hawes: I am from northwestern Pennsylvania, originally. Small town of Greenville, Pennsylvania. Town of, I think it peaked around 8,500 people, and has come down some since. So, kind of a crazy space cadet from a small-town story.

SpaceFlight Insider: How did you get interested in the space business?

Hawes: I’m an Apollo kid. I was 13 when Buzz and Neil walked on the moon. I had followed, certainly through the Gemini and all the Apollo missions, and that just captured me. I had science teachers at the time [that] kind of helped feed that. And I decided I wanted to do that and to become an aerospace engineer. Seemed like a reasonable way to go pursue that. So, that’s what I did.

SpaceFlight Insider: So, you grew up there, went to high school there?

Hawes: Went to high school there.

SpaceFlight Insider: And then after that you went off to college?

Hawes: Went off to college. Went to the University of Notre Dame. And got my bachelor’s in aerospace engineering. And got hired right out of school by NASA Johnson [Space Center]. They were starting to staff-up, particularly to fly the Space Shuttle Program.

SpaceFlight Insider: So, this would have been what? The 70s?

Hawes: Late ‘70s. ‘78. I went down to JSC [(Johnson Space Center)] and spent 33 years working for NASA.

SpaceFlight Insider: When you first hired on, back in the 70s, what was your first position?

Hawes: I was working in a group called payload operations. And we were trying to figure out how we were going to do experiments with the Space Shuttle, what was going to fly in the cargo bay. I got pretty quickly slotted into a group that was dealing with the commercial com[munication] satellites that were going to fly in the cargo bay and be deployed by the crews. So, that was kind of where my expertise was. And then post the Challenger accident, President Reagan decreed that the Shuttle was not going to be a launch vehicle for commercial satellites. And so, at that point, I started transitioning into space station work and some other work there at the Center. And that ultimately led me to transfer to NASA Headquarters doing space station work. And I stayed there and retired back in 2011 and went to Lockheed Martin.

SpaceFlight Insider: What was your last position when you were at NASA Headquarters?

Hawes: My last position was called Associate Administrator for Program Analysis and Evaluation. We did all the program reviews across the agency, had all the cost estimating teams, and things. So, I did that for three years. I transitioned Charlie in as Administrator.

Hawes: Charlie Bolden. And then retired in 2011. ______ [inaudible] retirement [and] 30 days later showed up on the Lockheed Martin rolls. And three years after that, they said, well, we think you really want to go to Houston and build spaceships. So, I’ve been doing that for the last eight years.

SpaceFlight Insider: When you first went to Lockheed, where were you?

Hawes: I was in the Washington, DC, area. In their Crystal City, Virginia, office, doing kind of the agency liaison job. Working back with NASA. Working with the White House. Helping some with educating staff on the Hill, but more the agency folks.

SpaceFlight Insider: And then you did that for three years and . . .

Hawes: Did that for three years and then they decided that they wanted somebody to go build Orion. So . . .

SpaceFlight Insider: And that was in Houston?

Hawes: Yeah, Orion, the program, is based in Houston. But we build all over the country.

The Artemis-1 Orion crew module under construction at NASA’s Michoud Assembly Facility (MAF) in New Orleans, La. Credit: Scott Johnson / SpaceFlight Insider

SpaceFlight Insider: I’ve been to Michoud [(Assembly Facility (MAF))], and I guess the initial assembly . . .

Hawes: The main structure is built-up in Michoud. It’s machined in Illinois and Los Angeles. And then it’s put together and welded in Michoud. And then it goes here to Florida. And all the rest of the structure and our harnesses and everything else gets put in. And so, I’m really mostly on the road because we have operations in Sunnyvale, California, Denver, Houston, New Orleans and Florida. And a little bit of support from a couple of other, like we have some work that’s done at Lockheed Martin Aero in Fort Worth. We have some stuff in Owego, New York. So, there’s a few additional branches that helped us out.

SpaceFlight Insider: When you were working back with NASA and doing some space station work, I’m from . . . Alabama, and mainly cover Marshall [Space Flight Center (MSFC)], did you spend any time up there?

Hawes: Yeah. Oh, absolutely. Lots of time at Marshall. I was early in the Space Station Freedom era. I ended up as the head of utilization and operations and so, of course, the utilization job is largely Marshall. You know, and the POC [(Payload Operations Center)] there and building up that capability. I had the funding for all the new facilities that we were building for operations for Space Station Freedom, and then it rolled into ISS [(International Space Station)].

International Space Station (ISS) modules under construction at NASA’s Marshall Space Flight Center in Huntsville, Ala. Credit: NASA

SpaceFlight Insider: I remember, years ago, you used to be able to, I forgot which building it was, but you could go in and watch the US modules being built.

Hawes: That’s right, yeah. They were actually welding the US modules right there on site. [Building] 4078. Something like that. But yeah, lots of time in Marshall. Lots of time back in Johnson [Space Center]. And Florida, of course.

SpaceFlight Insider: But you’ve now been with Lockheed, and on the Orion program since . . .

Hawes: I’ve been doing the Orion program manager job for eight years. Since 2014.

SpaceFlight Insider: And there’s probably not a typical day, but if you had to pick one, . . . probably not right now, it’s probably hectic now, but if a year ago, I’d followed you around for a day, what would that look like?

Hawes: A lot of meetings with NASA. A lot of meetings dealing with . . . an issue with our own internal manufacturing, or it’s one of our key suppliers. It could be trying to resolve issues a couple of tiers down in the supply chain. It may be doing interviews. It may be talking to staff up on the Hill. It can be any and all of that.

SpaceFlight Insider: So, you still do some political type . . .

Hawes: I do briefings. I don’t do lobbying, per se, but I do briefings.

The EFT-1 Orion crew module (covered by a portion of the Launch Abort System (LAS)) sits atop its United Launch Alliance (ULA) Delta IV Heavy launch vehicle in 2014. Credit: Jared Haworth / SpaceFlight Insider

SpaceFlight Insider: Okay, let’s move over to . . . Orion itself. I was lucky enough to be down here for EFT-1 [(Exploration Flight Test – 1, the first flight of Orion)], and saw that launch. I guess you were down here too?

Hawes: I was down here too.

SpaceFlight Insider: What were you doing? You said you’d been . . .

Hawes: I was program manager already. I had come in over the summer to replace Cleon Lacefield, because Cleon retired. And back then the control center we used was, since ULA [(United Launch Alliance)] was conducting the launch, the NASA and Lockheed teams were actually over in Hangar AE, the Mission Director Center there in Hangar AE.

SpaceFlight Insider: If I sat the Orion EFT-1 vehicle next to this Artemis 1 vehicle and looked outside and inside, obviously that one back then was black, and was it . . .

Hawes: That’s the first one. This one’s silver, not black.

SpaceFlight Insider: Was the intention always to put the silver reflective coating on, or was the . . .

Hawes: That evolved pretty quickly as a better thermal control coating. Better emissivity than the black tile. I think the black looks better myself – but I’m kind of partial – to the silver. But yeah, it’s a better thermal . . .

SpaceFlight Insider: Is the black tile still under . . .

The EFT-1 Orion crew module floats in the Pacific Ocean after splashdown on Dec. 5, 2014. Credit: U.S. Navy

Hawes: Yeah. That’s just a silicon oxide tape that’s on top of the tile. And the other thing that you’d see is that we had a dummy service module for EFT-1. And so, here we’re really flying the first full up ESA [(European Space Agency)] service module. That’s the other big, obvious, external change that you can see. The other thing, when we did EFT-1, is we flew most of the critical systems of the spacecraft, but we didn’t fly, necessarily, all the strings of redundancy because it was a short, four-and-a-half hour, test flight. Here we’re flying all the flight computers, all of the com[munication] gear, all of the power distribution gear. We’ve got all the interfaces with the ESA service module. We don’t have the crew controls and displays. And we don’t have some of the air-revitalization system.

SpaceFlight Insider: In the Artemis 1 Orion, is there some environmental control / life support?

Hawes: Well, you’re maintaining pressure. You have air. You have thermal control.

SpaceFlight Insider: If I was in there, could I breathe?

SpaceFlight Insider: Okay. So, there’s not an active . . .

Hawes: There’s not an active, what we refer to as, air-revitalization. So, you’re not getting that refreshed. You’re not getting the carbon . . .

SpaceFlight Insider: Whatever was in there when you shut the door, once I’ve used that up, I’d be in bad shape?

The Artemis 1 Orion crew module sits atop the European Service Module at NASA’s Kennedy Space Center. Credit: NASA

Hawes: Yeah. You could bring your oxygen tank. You still have CO2 scrubbing [issues], although I think we have some of the CO2 scrubbing, but it’s not going to get strongly exercised.

Hawes: Thermally, we’re okay.

Napier: Pretty active thermal, from an ECLSS [(environmental control and life support system)] standpoint?

Hawes: Yeah, thermally we’re okay. Because we’ve got the full . . .

Napier: So, you wouldn’t freeze.

SpaceFlight Insider: I probably couldn’t go to the restroom either?

Hawes: We do not have the waste management system. That is true. We do not have that.

SpaceFlight Insider: What is missing from Artemis 1? Obviously, the full life-support?

Hawes: Those are the biggies. So, it’s the waste management system. The exercise device. Some of the other, we call it generally, crew equipment. We have a seat in there for Moonikin Campos [(a sensor-laden manikin wearing an Orion Crew Survival System (OCSS) suit)], so we’ll have . . .

SpaceFlight Insider: Is there just one seat? I know there’s two other semi-torsos, but it’s just one seat?

Hawes: Yeah, and that’s for the Moonikin. And the torsos are kind of mounted to the bulkhead there.

Napier: And then the mass simulator where the pilot would sit. There’s no seat.

SpaceFlight Insider: Is that just like a big lead weight or . . .

The interior of the Artemis 1 Orion crew module on its flight to the moon, with Moonikin Campos on the left and a mass simulator on the right. Credit: NASA

Hawes: Well, an aluminum weight, more likely. Yes. And then we don’t have displays. So, there are three display panels that will go in. And then there’s switches along with them because we’re kind of a hybrid cockpit, if you will. And then some of the air-ducting, and CO2 scrubbing, and all that, we did not put into Artemis 1. Most of that is installed now on Artemis 2, already. The crew displays are ready to go in. We’re working an issue with fasteners, but . . .

Hawes: Artemis 2 is in the O&C [(Neil Armstrong Operations and Checkout Building)].

SpaceFlight Insider: Here at KSC [(Kennedy Space Center)]?

Hawes: Yeah. We’ve already done initial power-on testing. And now we’re doing that with the service module. So, we’re in assembly of some of the final components and the crew module. And the next testing sequence with the crew module is early October. And then mid-December, based on flying Monday [(August 29, 2022)], we expect to have all the components to transfer from 1 to 2 . . .

SpaceFlight Insider: That was my next question, you’re going to take some stuff out of 1 and . . .

Hawes: We have 10 components that have to move from 1 to 2. And we expect those to be . . .

SpaceFlight Insider: Is that avionics or . . .

Hawes: Most of it’s avionics. Some of the crew systems stuff, like the seat, we can reuse. I’ve got a list, but it’s mostly avionics. And so, like the IMUs [(inertial measurement units)], and that’s a debate where we may need to have Honeywell, over at Clearwater[, Florida], re-calibrate the IMUs. And that takes a little time, but fortunately that’s West Coast Florida and East Coast Florida, so it’s . . .

The Artemis 2 Orion crew module under construction at NASA’s Kennedy Space Center. Credit: UPI

SpaceFlight Insider: That’s coming out of 1 and going into 2?

Hawes: That’s coming out of 1 to 2. The phased array antennas are coming out of 1 and go to 2.

SpaceFlight Insider: What’s the GPS do for you? Is that for landing?

Hawes: Yeah. Predominantly for landing.

SpaceFlight Insider: What did you, backing up to EFT-1 Orion, I guess the heat shield was the big thing you wanted to learn about then, what did you learn from EFT-1?

Hawes: So, when we put EFT-1 together, as a candidate mission, we looked at kind of a parade of the high-risk things that we hadn’t done for a long time. And it turned out that we were able to capture pretty much the top 17, or so, high risk events, mechanisms, those kinds of things. So, first and foremost, the redo of Avcoat. We hadn’t used Avcoat since Apollo. And even though we changed how we manufacture and apply it for Artemis 1 . . .

SpaceFlight Insider: Back then it was smaller blocks and it’s bigger pieces now? Or have I got it backwards?

Hawes: Well, we called it, it was bigger pieces then. We called it monolithic. And if you think about it, the heat shield is this titanium frame, a multi-layer composite skin that’s, literally, fastened to that. And then, for EFT-1, we actually glued a honeycomb structure on top of that, and filled all the cells with Avcoat. And it tended to crack. It was a pain to manufacture. So, we proposed using more of a block-style, like the tiles, to NASA. Did a bunch of testing. There’s still some folks that, I would say, are nervous. I mean, I’ll just be honest. There are some folks that really want to see that demonstrated. So, that’s the top flight objective for this mission.

Napier: Mike, is it safe to say, because the large aeroshells that we created for Mars, with Curiosity and Perseverance, were block, they’re just PICA [(phenolic impregnated carbon ablator)], did we pull from those . . .

Hawes: Different material. Well, yeah, all . . .

Napier: From that learning of how to do block . . .

SpaceFlight Insider: I don’t know that I remember that. Y’all did the heatshields for . . .

Hawes: We do all the Mars aeroshells. Now, the material is PICA. Those are the two competing materials for the high-speed reentries. So, that reentry system expertise is something that we have across the company. And the folks that worked on Orion are also the folks that have worked on the planetary missions. And, in fact, my heat-shield lead is now over working MAVIS [(Mars Ascent Vehicle Integrated System)] and the sample-return missions. Darn it.

The Artemis 1 Orion heatshield, prior to mating with the crew module, at NASA’s Kennedy Space Center. Credit: NASA

SpaceFlight Insider: So, one of the big things you want to test out of this mission is the new construction method, or the new assembly method, for the heatshield?

Hawes: That’s right. And so, that’s a biggie. The other things that we did on EFT-1 is we demonstrated all of the critical separation events. As you’re going up, on launch, you’re jettisoning the panels that surround the service module. You’re jettisoning the abort tower. Coming back home, you’re separating the crew and the service module. So, all of those pyrotechnic devices were a big deal for EFT-1. But you have to do those every mission. So, those are part of . . .

SpaceFlight Insider: Has any of that changed? Or are you pretty much using . . .

Hawes: No. Those have pretty much stayed the same. But the other thing, like I say, we didn’t have full redundancy. Like, we didn’t have all three flight computers. We had all the phased array antennas, but some other systems we were single-string on. And now, it’s not just that you have the full redundancy, but you’re also operating with that forward _____ [(inaudible)]. So, you have flight software that’s sensing, and making swaps, and moving. We have a safe mode in the spacecraft for certain failures, and the spacecraft itself goes into a safe mode. So, a lot more software. A lot more fault detection / enunciation-type capability. A lot more data. We have on the order of 2,500 measurements on what we call DFI, or developmental flight instrumentation, on this mission that are all, a whole bunch of those are, heat shield. But they’re all over the spacecraft. And so, that’s going to feed the whole data analysis that then says okay, we have validated this design and now we’re going to go to production-mode and build the same thing.

SpaceFlight Insider: On this mission, Artemis 1, Orion is going to be coming back in at what? 25,000+ miles an hour?

SpaceFlight Insider: EFT-1 was not quite that?

Hawes: EFT-1, . . . we came in at 20,000 [miles per hour].

Hawes: Yeah, 4,000 degrees temperature [and] 20,000 [miles per hour].

Napier: Artemis 1 is going to see upwards of 5000 degrees on this heatshield.

Hawes: Substantial and the heat load is not a linear function. It’ll be a good test.

SpaceFlight Insider: Okay. You said Artemis 2 is under construction. And if Artemis 1 flies Monday, hopefully, and you get your stuff back and there’s not any major problems with it, when are you hoping to have Artemis 2 ready to go?

Hawes: So, we’re hoping that Artemis 2 can go by the end of ‘23, early ‘24.

SpaceFlight Insider: And that’s just Orion? Obviously, you’ve got to have a rocket that’s ready?

Hawes: NASA is really pushing us to turn over Artemis 2 by March of ‘23. Our date says a little bit later. So, we’re working as you’re testing. We can change assembly tasks . . .

SpaceFlight Insider: That’s not too far? We’re August of ‘22 — eight, nine months?

Hawes: We test the components individually. So, we started the CM [(Orion Crew Module)] testing. We’re doing the SM [(European Service Module)] testing. We’ll follow this general track of individual testing. We have to do acoustic testing, thermal testing. Get all those components in. And we’ve had some debates of . . .

SpaceFlight Insider: Do y’all do all of that here, or does it have to go up to . . .

Hawes: It’s all here. And that’s the key. Keeping it at this module level is what allows us to do it here rather than having to go off to separate facilities like, Artemis 1 we took to Plumbrook[, Ohio — the location of NASA’s Neil A. Armstrong Test Facility –] and did everything up there. But that rooted our models so that now we can do the work here. And then you put the two together and you have all the series of a flow that’s the CSM [(Crew and Service Module)] flow together, and then to turn it over to EGS [(Exploration Ground Systems)].

SpaceFlight Insider: And the Artemis 2 service module is here?

The Artemis 1 Crew Module Adapter, installed between the crew and service modules at NASA’s Kennedy Space Center. Credit: NASA

SpaceFlight Insider: And I know that’s a European project . . .

Hawes: Well, you’ve got the European piece and then you have the upper ring – called the Crew Module Adapter . . .

SpaceFlight Insider: Do they make that in Huntsville?

Hawes: No. We make it.

SpaceFlight Insider: Okay. There’s some . . .

Hawes: Huntsville has made the adapter, the transitions between the rocket and Orion.

SpaceFlight Insider: Okay. Where the CubeSats are?

SpaceFlight Insider: And then I think they also make the LVSA [(Launch Vehicle Stage Adapter)]?

SpaceFlight Insider: Or Teledyne Brown?

The Artemis 2 Launch Vehicle Stage Adapter (LVSA) under construction at NASA’s Marshall Space Flight Center. Credit: NASA

SpaceFlight Insider: To sort of wrap up, you’ve been with NASA, and now Lockheed Martin, all together, many, many years. And you’ve been working on this for many, many years. How does it feel to finally get to, hopefully, three days before launch?

Hawes: Well, it’s kind of amazing to be just three days before launch. It’s really been kind of a driving theme of my career to get us back to the moon. So, it feels pretty good to be here.

SpaceFlight Insider: Do you plan on staying on a while?

Hawes: I plan on going to be a full-time grandfather.

SpaceFlight Insider: Where would that be?

SpaceFlight Insider: You live in Houston now?

Hawes: I bounce between Houston and Virginia. Actually, as I say, my wife and my house are in Virginia, along with my daughter and her family, so . . .

SpaceFlight Insider: You’re not going to be with the program until Artemis 3 [– the planned first lunar-landing mission]?

Hawes: No. I’m going to retire after this mission.

SpaceFlight Insider: Right after this mission?

Hawes: I already have my successor, Tonya Ladwig.

SpaceFlight Insider: Has that been announced?

Hawes: Well, it’s in the rumor mill. I don’t think we actually put anything out.

Tonya Ladwig, Lockheed Martin Space Systems Company, Vice President for Human Space Exploration, and Orion Program Manager. Credit: Lockheed Martin

Napier: Well, it’s public, but it wasn’t announced. She’ll be here in a day or two, too.

Hawes: Yeah, Tonya is the incoming program manager, and she’s actually doing all the day-to-day stuff with Artemis 2 and beyond, now, so that I could focus on . . .

SpaceFlight Insider: So, you’re done as soon as this thing launches?

Hawes: No, when the mission’s done.

SpaceFlight Insider: Oh, in 42 days?

Hawes: Remember, Orion is 42 days. The rocket is . . .

SpaceFlight Insider: So, you’re done sometime, hopefully, in late October?

Hawes: Yeah. That’s the plan.

SpaceFlight Insider: Where in Virginia?

Hawes: Winchester. We’re building a house that’s kind of the north end of the Shenandoah Valley.

SpaceFlight Insider: Well, that’s a good place to go.

Hawes: Yeah. It’s a pretty place.

Artemis 1 ended up launching, on its third attempt, at 1:47 a.m. EST (06:47 UTC) Nov. 16, 2022. Its Orion crew capsule has now orbited the Moon and will splashdown off the coast of Baja California on Dec. 11, 2022.

Tagged: Artemis 1 Artemis 2 Artemis I Artemis program ESA Human Space Flight Kennedy Space Center Lockheed-Martin NASA Orion Space Launch System The Range

Scott earned both a Bachelor's Degree in public administration, and a law degree, from Samford University in Birmingham, Alabama. He currently practices law in the Birmingham suburb of Homewood. Scott first remembers visiting Marshall Space Flight Center in 1978 to get an up-close look at the first orbiter, Enterprise, which had been transported to Huntsville for dynamic testing. More recently, in 2006, he participated in an effort at the United States Space and Rocket Center (USSRC) to restore the long-neglected Skylab 1-G Trainer. This led to a volunteer position, with the USSRC curator, where he worked for several years maintaining exhibits and archival material, including flown space hardware. Scott attended the STS - 110, 116 and 135 shuttle launches, along with Ares I-X, Atlas V MSL and Delta IV NROL-15 launches. More recently, he covered the Atlas V SBIRS GEO-2 and MAVEN launches, along with the Antares ORB-1, SpaceX CRS-3, and Orion EFT-1 launches.

Your email address will not be published. Required fields are marked *

Notify me of follow-up comments by email.

Notify me of new posts by email.

© 2013 - 2023 Spaceflight Insider. Use of this site constitutes acceptance of our Privacy Policy.

Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously. CookieDurationDescriptioncookielawinfo-checbox-analytics11 monthsThis cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics".cookielawinfo-checbox-functional11 monthsThe cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional".cookielawinfo-checbox-others11 monthsThis cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other.cookielawinfo-checkbox-necessary11 monthsThis cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary".cookielawinfo-checkbox-performance11 monthsThis cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance".viewed_cookie_policy11 monthsThe cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data.

Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.

Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.

Sound Button Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet.